The Lighting Process

Technology + Art

The Carbon Fiber Light Series and Kozo Light Series are produced with manufacturing processes originating from the aerospace and motorsport industries. It is extremely fortunate that Fuller Design is located in Indianapolis, Indiana, (the home of the Indy 500 and the number one motorsport economy in the world) and is able to access these resources and technology.

The Wood Veneer Arc Light Series (domestic, exotic, and custom) feature premium natural domestic and exotic veneer options with unlimited veneer selections, sizes, and shapes. Also available are manmade reconstituted veneers as an environmentally friendly alternative. The light forms are produced using commercial veneer pressing technology, materials, and adhesives.

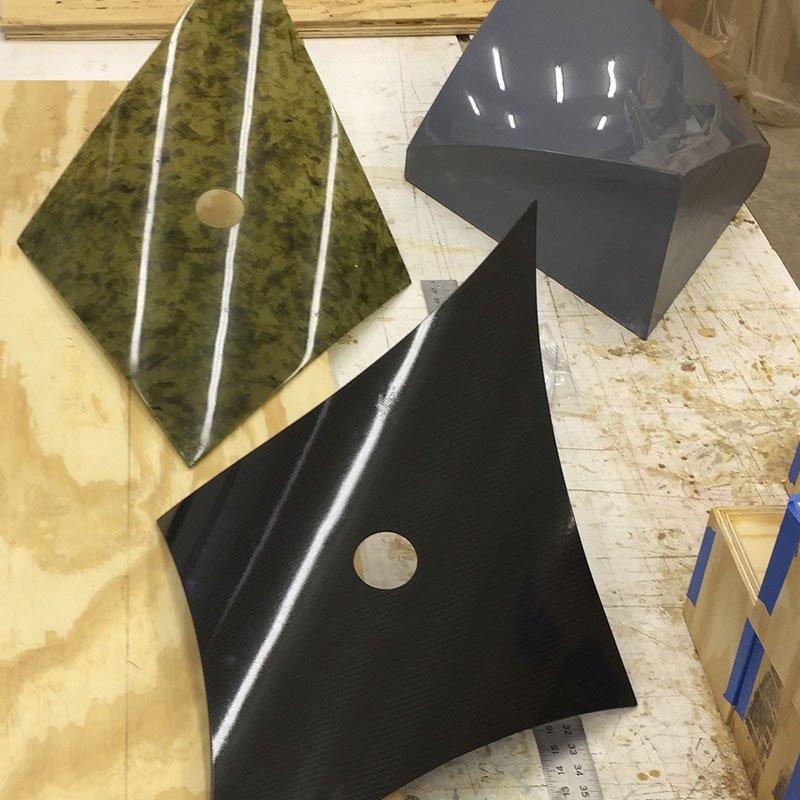

Carbon Fiber Light Series

Carbon Fiber filaments that are woven into fabric are produced on a size scale comparison of roughly 1/8 the diameter of the human hair; when combined with epoxy resin under pressure yield a strength that is 10 times stronger than steel and 5 times lighter.

-

The Carbon Fiber Light Series is created using a molding technology process specifically used to make high performance racing and aerospace products. Carbon Fiber proprietary weave fabric produces a final product that exhibits a combination of high strength and stiffness to low weight which is desired by the racing and aerospace industries. Carbon Fiber filaments that are woven into fabric are produced on a size scale comparison of roughly 1/8 the diameter of the human hair; when combined with epoxy resin under pressure yield a strength that is 10 times stronger than steel and 5 times lighter. Carbon Fiber is considered the “super material of the decade” for this reason.

The CFF Arc Light (Carbon Fiber Filament) is produced by the same process as the other Carbon Fiber lights using the epoxy resin infusion vacuum molding technology. The strong black graphic filaments that you see are thousands of carbon fiber filaments and some you cannot see as a CF filament is 1/8th the diameter of a human hair. By alternating layers of the carbon fiber filaments with FG fine weave fabric, the filaments seemingly float in a space of epoxy resin. The combination of process and multiple layers of materials also creates a translucent diffusion of the light form.

The vacuum epoxy infusion process used to mold each piece is slow and all materials are carefully laid up by hand for each light form. The Fuller Design Carbon Fiber lights have few if any competitors in the United States.

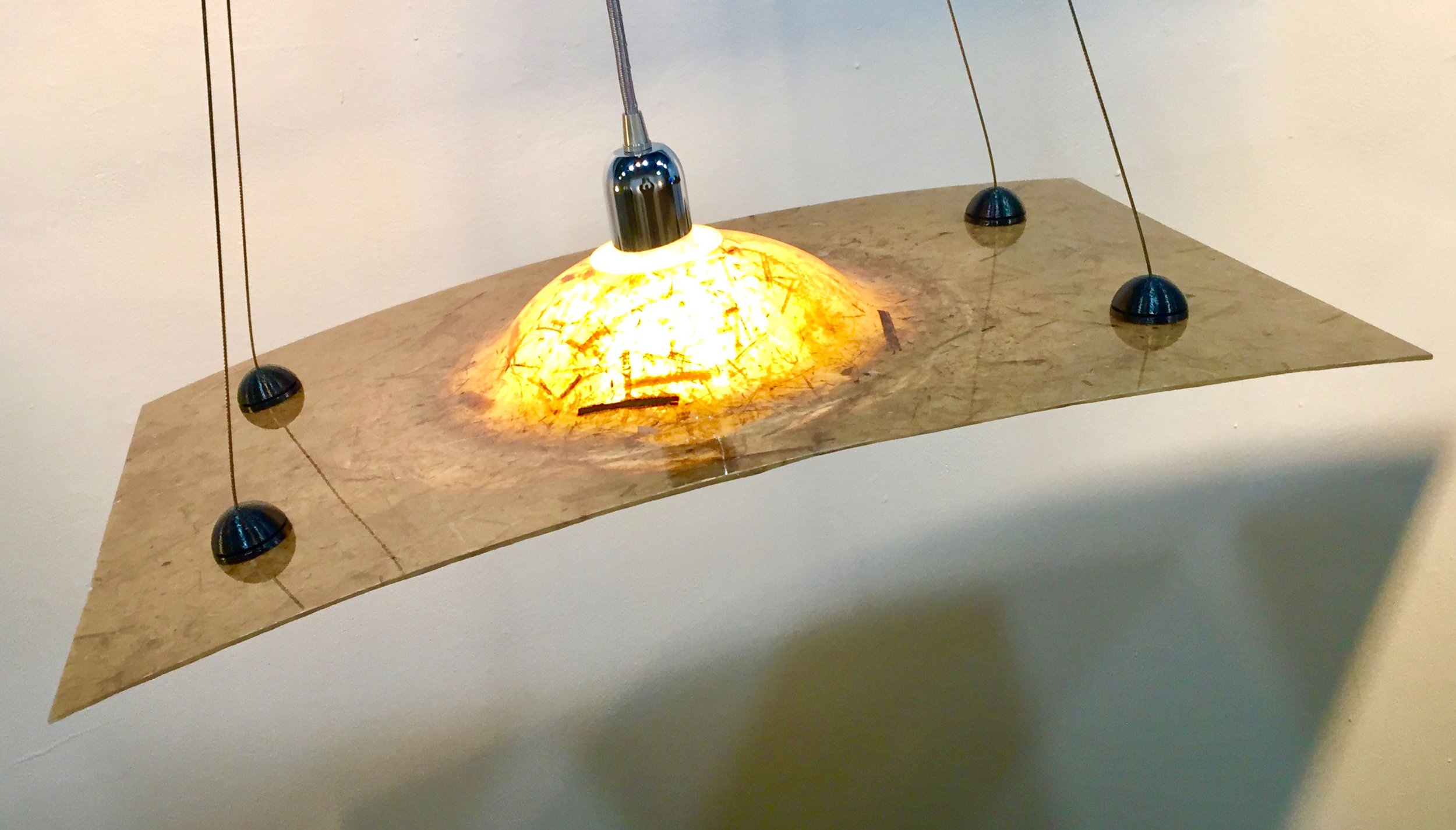

Kozo Light Series

The Kozo Light Series feature authentic Japanese papers made from traditional Japanese organic materials including real mango leaves and banana tree materials (other selections to be added) and are used in conjunction with the same process used in the making of the Carbon Fiber Light Series. We have found that this process using Japanese papers is original and cannot be found anywhere else globally.

-

Using the same high tech manufacturing carbon fiber molding process as the Carbon Fiber lights, Japanese papers are substituted for the carbon fiber fabric along with special proprietary weave fiberglass filament fabric, creating a similarly strong lightweight part. The proprietary process and specific layups of the Japanese papers create a visual translucency that highlights the detailed beauty of the papers. The Kozo lights and processes associated in making them are not replicated anywhere else in the world and are truly one of a kind globally.

-

Japanese paper making technology originated over 1300 years ago; while manufacturing processes have naturally advanced, the final products uniqueness and beauty is still intact and prevalent. The papers used in the lights are made of (Kozo) mulberry tree fibers as the base material of the Mango and Banana papers. The Mango paper features real organic mango leaves and inclusions that are gathered once fallen making them eco friendly and earth responsible.

The Banana paper features real organic banana tree inclusions cultivated from stems which are thrown away once the banana fruit is harvested. Using these discarded stem material aids in recycling and is a responsible eco friendly choice.

Plans to expand the Kozo paper offerings per model are in the future along with developing complementary new forms to showcase these and new Japanese papers.

Wood Veneer Light Series

The Wood Veneer Light Series provides select domestic and globally available veneer options; with the new Custom Series unlimited veneer choices and an infinite number of shapes are possible.

-

The Wood Veneer Light Series features premium natural domestic and exotic veneer options with unlimited veneer selections, sizes, and shapes. Also available are manmade reconstituted veneers as an environmentally friendly alternative. The light forms are produced using commercial veneer presssing technology, materials, and adhesives. The top coat Danish Oil finish is hand applied, seals and protects the veneer, while at the same time making the veneer harder, another bonus. Special matching stains and finishes are also available to the “Custom” category customer.

While offering (5) domestic and (5) exotic veneers, a customer can select any veneer that is available globally including special figuring or cut at the veneer mill. Matching the wood veneer species to companion veneer/wood furniture or cabinetry is also an option. While the standard finish is Danish Oil special color matching can be achieved. All other options outside of the wood veneer arc lights presented with pricing will fall into the “Custom” category with additional labor and material prices as specified.

-

Wood veneers are available in both domestic and exotic options as well as customized selections.

Domestic wood veneer options include maple, red oak, cherry, white oak, and walnut.

Exotic wood veneer options include ebony, zebrawood, anigre, santos rosewood, and pommele sapele.

See Glen Fuller for customized wood veneer selections.

-

Wood veneer arc lights are available with multiple customization options including size, shape, and veneer.

40” x 40” mold footprint for unlimited size options

Shape options include basic geometrical forms (rectangle, square, round, oval, triangle) and organic asymmetrical forms with unlimited options

Unlimited veneer selections and combinations; the top and underside can be different veneers

When building a custom wood veneer arc light you will be working directly with designer Glen Fuller throughout the interactive design process.

Work side by side with Fuller Design to get the exact light that you desire

Select a form and size

Select a veneer or veneers; the top and underside can be different veneers

CAD drawings can be provided by Fuller Design per request

Arrange for delivery or pick up if local; outside of Indianapolis area will require custom shipping requirements (shipping carton, etc.)

-

The light fixtures we suggest be installed by a professional electrician. All electrical components are UL approved by their manufacturer; the components include the canopy, electrical cable, socket, and electrical connectors.

Additional specifications and recommendations for hanging the lights, installation and also bulb recommendations are below. Bulbs are not included with the fixture and need to be ordered separately from the bulb manufacturers/lighting stores. We have listed resources and recommendations below to assist you. Please contact us if we can assist in any way.

-

Fuller Design recommends the following bulbs and illumination: Bulbs & Illumination Recommendations (PDF)

-

Fuller Design recommends the following installation: Membrane and Arc with Dome Light Installation Recommendations (PDF)